Standards Australia Slip Resistance Handbooks

Standards Australia & CSIRO Handbook HB 197 An Introductory Guide to the Slip Resistance of Pedestrian Surface Materials is seen as best practice for satisfying the slip resistance requirements of new floor surfaces. The handbook provides general commentary on the slip resistance test methods, classification, basis for specification and guidance for designing ramps and sloped areas.

Many people may be aware of Tables 3, 4 & 5 of Standards Australia & CSIRO Handbook HB 197 which provides minimum slip resistance classifications for specific locations. There is much more information and detail that must be considered beyond simply extracting the classifications from the tables. Additionally, existing surfaces that do not meet the recommendations of HB 197 may not necessarily be unsafe, a risk assessment and possible control measures should be evaluated by a qualified expert.

Standards Australia publishes two slip resistance handbooks:-

- HB197:1999 An Introductory Guide to the Slip Resistance of Pedestrian Surfaces

- HB 198:2014 Guide to the Specification and Testing of Slip Resistance of Pedestrian Surfaces

In the years following the publication of HB197, many designers and operators took the view that this was an optional guideline (not a standard) and that compliance was a choice. Insurers quickly disagreed when courts were awarding significant payments to claimants in slip cases and in general settled claims where a design did not meet the minimum recommendations of this Handbook.

Handbook 197 was intended as an interim publication and the recommendations contained within were intended to be MINIMUMS. Those who believed that a complying selection would prevent any problems often found out the expensive way after a series of problems with products in service. Handbook users who simply designed by skimming the tables found in the Handbook, often made incorrect assumptions. Perhaps the most common was because the tables often recommended results by more than one test method, for example:

Table 3 lists both Ramp (R ratings) and Pendulum (Z, Y, V ratings). For a building entry foyer this table recommend an R10 ramp and/or an X pendulum. Some users therefore determined incorrectly that an R10 was equivalent to an X. In fact there is no direct correlation between Ramp / Pendulum or other test method results.

R10 does not = X or Y or W or P2 or P3 etc.

HB198 published in 2014 does not replace HB197, however there is some additional information and some clarification of some of the most questioned and criticised aspects of the original handbook. Most notable aspects of HB198 are:-

- R11 minimum (or P4 ) now recommended for external walkways (R10 is deemed inadequate)

- Prescriptive recommendations under the Australian Buildings Code Board (ABCB) for all classes of buildings including for the first time Residential buildings for stairs, ramps and landings

- Acknowledgement on the effects of wear on slip resistance and recommendation to use wear conditioning of samples before measuring slip resistance (AWT Accelerated Wear Testing)

SA HB 198:2014 Handbook Guide to the specification and testing of slip resistance of pedestrian surfaces

5.2 Classifications for particular applications

Table 3B provides guidance for pedestrian surfaces for particular applications. The values represent a consensus view of Committee BD-094, although not all experts agree on all values. The values in Table 3B have been determined by the following process:

- Applications and corresponding values were selected initially from HB 197:1999.

- A subcommittee of Committee BD-094 modified some applications and values, and these were further modified during the review process.

- The contents of Table 3B are subject to further review by Committee BD-094, in its ongoing project to provide guidance on specifying and testing for slip resistance.

For completeness, Table 3A is also reproduced here.

There are some fundamental differences in the purpose and nature of Tables 3A and 3B.

Table 3A applications and values have been determined by the Australian Building Codes Board for use in regulations based on the National Construction Code NCC. It provides the minimum wet pendulum test or oil-wet inclining platform test classifications that are deemed-to-satisfy specific applications in buildings covered by the NCC. These values may be used as acceptance criteria in a range of situations, including those where the building incorporates only the minimum regulated NCC requirements for handrails, lighting and the like.

Table 3B applications and values have been determined by Committee BD-094 for use in applications that are not regulated by the NCC. It provides wet pendulum test or oil-wet inclining platform test classifications for applications where the NCC does not specifically require slip resistance. The applications listed are some of those for which slip resistance is warranted for reasons other than NCC compliance. The use of these values should be in the context of design, which also considers abnormal wear, maintenance, abnormal contamination, the presence (or otherwise) of water or other lubricants, the nature of the pedestrian traffic (including age, gait and crowding), the footwear (or lack thereof), slope, lighting and handrails.

| TABLE 3A | ||

| MINIMUM WET PENDULUM TEST OR OIL-WET INCLINING PLATFORM CLASSIFICATIONS THAT ARE DEEMED-TO-SATISFY THE BUILDING APPLICATIONS IN THE NCC | ||

| Location | Wet Pendulum | Oil-wet |

| Stair Treads and Stairway Landings in Buildings Covered by NCC Volumes One and Two | ||

| Stair treads and a stairway landing (when dry) | P3 | R10 |

| Stair treads and a stairway landing (when wet) | P4 | R11 |

| Nosing for Stair Treads and Stairway Landings in Buildings Covered by NCC Volumes One and Two | ||

| Dry stair treads a stair non-skid nosing strip and a stairway Landing | P3 | |

| Wet stair treads a stair non-skid nosing strip and a stairway landing | P4 | |

| Ramps in Buildings Covered by NCC Volumes One and Two | P3 | R10 |

| Ramps not steeper than 1:14 gradient (when dry) | P4 | R11 |

| Ramps not steeper than 1:14 gradient (when wet) | ||

| Ramps steeper than 1:14 up but not steeper than 1:8 (when dry) | P4 | R11 |

| Ramps steeper than 1:14 up but not steeper than 1:8 (when wet) | P5 | R12 |

| NOTE: NCC compliance is demonstrated by achieving the values set out in this Table for either the wet pendulum test or the oil-wet inclining ramp test. It is not necessary to meet both criteria. | ||

| TABLE 3B | ||

| WET PENDULUM TEST OR OIL-WET INCLINING PLATFORM CLASSIFICATIONS FOR APPLICATIONS WHERE THE NCC DOES NOT REQUIRE SLIP RESISTANCE | ||

| Location | Wet Pendulum test | Oil-wet |

| External Pavements and Ramps | ||

| External ramps including sloping driveways, Footpaths’ etc, Steeper than 1 in 14 | P5 | R12 |

| External ramps including sloping driveways, foot paths etc, under 1:14, external sales areas (Markets), external car park areas, external colonnades, Walk ways, pedestrian crossings, balconies, verandas, carports, driveways, | ||

| Court yards and roof decks | P4 | R11 |

| Undercover car parks | P3 | R10 |

| Hotels, Offices, Public Buildings, Schools and Kindergartens | ||

| Entries and access areas including hotels, offices, public buildings, schools, kindergartens, common areas of public buildings, internal lift lobbies. | ||

| Wet Area | P3 | R10 |

| Transitional Area | P2 | R9 |

| Dry Area. | P1 (See Note 3) | R9 |

| Toilet Facilities in offices, hotels and shopping centres | P3 | R10 |

| Hotel apartment bathrooms, En suites and toilets | P2 | A |

| Hotel apartment kitchens and laundries | P2 | R9 |

| Supermarkets and Shopping Centres | ||

| Fast food outlets, buffet food serving areas, food courts and fast food dining areas in shopping centres | P3 | R10 |

| Shop and supermarket fresh fruit and vegetable areas | P3 | R10 |

| Shop entry areas with external entrances | P | R10 |

| Supermarket aisles (except fresh fruit areas) | P1 (See Note 3) | R9 |

| Other separate shops inside shopping centres – wet | P3 | R10 |

| Other separate shops inside shopping centres – dry | P1 (See Note 3) | R9 |

| Loading docks, Commercial Kitchens, Cold Stores, Serving areas | ||

| Loading docks undercover and commercial kitchens | P5 | R12 |

| Serving areas behind bars in public hotels and clubs, cold stores and freezers | P4 | R11 |

| Swimming pools and Sporting Facilities | ||

| Swimming pool ramps and stairs leading to water | P5 | C |

| Swimming pool surrounds and communal shower rooms | P4 | B |

| Communal changing rooms | P3 | A |

| Undercover concourse areas of sports stadiums | P3 | R10 |

| Hospitals and Aged Care Facilities | ||

| Bathrooms and en suites in hospitals and aged care facilities | P3 | B |

| Wards and corridors in hospital/aged care facilities | P2 | R9 |

NOTES TO TABLE 3B:

- The slip resistances of pedestrian surface materials set out in Table 3B are intended as guidance in the context of design for pedestrian safety, taking account other factors including abnormal wear, maintenance, abnormal contamination, the presence (or otherwise) of water or other lubricants, the nature of the pedestrian traffic (including age, gait and crowding), the footwear (or lack thereof), slope, lighting and handrails.

- The contents of Table 3B are subject to further review by Committee BD-094, in its on-going project to provide guidance on the specification and testing of slip resistance.

- The minimum classifications listed in Table 3B are P1 and R9. It is inappropriate for Table 3B to list the lower classification, P0, since there is no lower limit on Classification P0. Notwithstanding, some smooth and polished floor surfaces, which do not achieve Classification P1, may be considered to provide a safe walking environment for normal pedestrians walking at a moderate pace, provided the surfaces are kept clean and dry; however, should these surfaces become contaminated by either wet or dry materials, or be used by pedestrians in any other manner, then they may become unsafe. Therefore, the type of maintenance, the in-service inspection of floors, other environmental conditions and use should be taken in to account when selecting such products.

- When using the oil-wet inclining platform ‘R’ classifications, consideration should also be given to the determination and use of volumetric displacement ‘V’ classifications. In some cases, a specifier may choose either a particular combination of R and V values, or a more severe R value alone. For example: R10 + V4, or R11.

Further information can be provided by:

Standards Australia: www.standards.org.au

Safe Environments: www.SafeEnvironments.com.au

Slip Resistance Test Methods

There are a number of different test methods recognised by the Australian Standard for slip resistance 4586:2013. One of the most recognised is probably the ramp test with its R rating results – R9, R10 etc.

The Wet Pendulum Test is broadly being recognised as the most effective method, due mainly to the high likelihood of this test method being used to evaluate the suitability of a design selection after installation. The pendulum test is portable and therefore the test of choice for any forensic testing on site, which can be critical if there, has been a slip incident.

Test results achieved by different test methods have no direct correlation. However generally higher results achieved via one test method, will typically achieve higher results on other tests.

A product that is believed suitable following testing via one methodology may prove unsuitable following a different test type methodology being employed.

Standards Australia does publish slip resistance handbooks HB: 197 & HB: 198, to provide guidance as to how much slip resistance is a minimum requirement for various applications. A design that does not comply with these handbook minimums will leave the parties involved vulnerable to a litigation should a slip incident occur.

Pendulum test apparatus being used on-site

Wet Pendulum Test

The pendulum test apparatus measures friction (CoF or Coefficient of Friction) and provides results as BPN (British Pendulum Number). The pendulum test is portable and therefore is frequently used on site as well as in laboratory conditions. It is one of the approved test methods under the Australian Standards AS4586:2013 & AS4663:2013

The test has a number of advantages over other test methods.

- Portable and used for on-site testing

- The most likely test to be used in an investigation following a slip incident

- Wet test using water – which is the most commonly encountered contaminant

- Consistent results with minimal operator impact

- Used in conjunction with accelerated wear testing (AWT)

The results in BPN are grouped into categories of P0, P1, P2, P3, P4 and P5 (P5 is the highest). Pendulum tests carried out prior to July 2013 were done with a slightly different method of preparation and results were classified as (lowest) Z, Y, X, W, V (highest). Tests provided under the previous method with Z – V results are still current, however they cannot be directly stated as equal to current P0 – P5 results.

Wet Barefoot Ramp Test

Wet barefoot ramp slip resistance testing is used for applications where it is expected that the majority of users will be in bare feet. This test is carried out on the same ramp apparatus as the oil ramp test except the test panel has a stream of water (no oil) and with the test operator not wearing any shoes.

As with the oil-wet ramp test, the panel of the tiles to be tested are inclined to the point where the barefoot operator slips and the angle of the panel/ramp is measured. The angle results are then classified as either A, B or C (highest).

Swimming pools, their surrounds and their amenities are by far the most common design applications where wet barefoot test results are considered. – C rating is recommended for swimming pools.

Oil Wet Ramp Test

The Oil-wet Ramp Test (commonly referred to as the “Ramp Test”) provides scores that are widely recognised by most designers from their R – rating results: R9, R10 etc. The mechanism of achieving these results however is often poorly understood, as are the limitations of this test method. There are very significant limitations to the ramp test and the creation of designs and specifications using ramp test results alone has lead to many problems for designers, their clients and indeed users and operators of facilities.

An investigation of slip resistance following an accident will almost certainly not involve the ramp test results, but rather will consider on-site pendulum testing. It therefore follows that to design a floor without knowledge of the pendulum results of the floor surface selected is a significant risk.

A large part of recognising the ramp test’s limitations is obvious when the test method is explained: Approximately ½ a square meter of tiles to be tested is placed on a horizontal ramp panel, which is then inclined to the point where the test operator walking on it “slips”. The steepness of the angle of the ramp panel is then measured and given a category rating from R9 to R13.

The following is a brief list of the limitations of the ramp test method:-

- Ramp angle results are simply a made-up number – they bear no correlation to the slope of a surface on which the tile can be used.

- The ramp test is not portable and can only be done in laboratory conditions

- The test shoes are a specific type of heavily profiled shoe and this type soled shoe may not reflect the footwear of the majority of users for the design application.

- Oil/water mix is the contaminant used on the test pieces this may not reflect the conditions of the design application. For example: will oil be present?

- A slip incident investigation will almost certainly involve conducting a Pendulum Test on-site. A ramp result used to make a design selection will carry little weight against a poor pendulum result conducted after a slip.

- There is no wear testing procedure or data bank following wear for the ramp test method

- Virtually all of the latest updates in the Australian Standards refer to pendulum testing methodology

Tortus – Dry Floor Friction Test

The Tortus test is conducted with a simple mechanical apparatus that measures the coefficient of friction (CoF) created between the tile and the device. The Tortus test is conducted on clean dry surfaces only and results are classified as either D1 (If friction was > 0.4 CoF) or a D0 (If friction was > 0.4 CoF).

Displacement Volume Test

The Displacement Volume test essentially measures the surface profile amount of a ceramic tile or other flooring product. It is intended be an indicator for deliberately patterned products with raised dots, pyramids, squares, circles, ribs, ridges etc. Flat textured surfaces will generally not achieve a result on this test however some extremely coarse textured surfaces of applied finishes may achieve a score in the lowest V4 category.

Ratings are V4, V6, V8 or V10 (highest).

Ratings are V4, V6, V8 or V10 (highest).

Profiled surfaces have generally received limited acceptance in the Australian market, and this limited acceptance has generally declined even further since the publication of HB198 in 2014.

The limitations of profiled surfaces include:-

- The relatively poor performance under accelerated wear testing(AWT)

- The relatively poor durability under heavy traffic

- A propensity to trap soiling with certain designs

- Relatively poor handling of wheeled traffic

- Recognition by the newer handbook HB 198 that a higher rated flat product is a suitable alternative to a profiled product. For example: an R11 flat tile may be suitable in lieu of an R10 tile with a profiled surface rated as V4

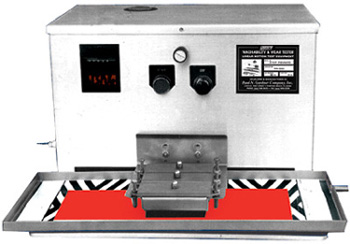

Accelerated Wear Test

The 2013 version of the Australian Standard 4586, now recommends the application of wear to the items prior to slip resistance testing, where there is a requirement for long term durability of slip resistance.

AWT (Accelerated Wear Testing) provides an indication of how the slip resistance of an item will perform during long term use. The most common wear application is 500 wear cycles (or scrubs) by the laboratory wear apparatus as shown. The application of 500 wear cycles is an excellent method of rejecting poorly performing products that loose too much of their initial slip resistance following installation and the initial handover period.

Application of 5,000 wear cycles is excellent for predicting which products will perform the best for the long term in heavy duty applications such as busy public access spaces for transport infrastructure, commercial buildings, shopping centres, sporting facilities etc

Following the application of wear, the item is then tested with the Pendulum as per the normal pendulum test method. As the pendulum essentially measures the CoF (Coefficient Friction), these results can be correlated to what are considered known requirements of CoF for safe walking. Most experts will agree that a floor measured with a reading of greater than 35 BPN (= 0.35 CoF) is inherently safe for normal pedestrian access. The minimum slip resistance recommendations found in Handbooks 197 & 198 recognise that all items lose some amount of slip resistance and take this into account in the recommended minimum. Therefore a product that scores 35BPN out of the box is very likely to score much lower than this after use.

AWT is an excellent predictor of the real world floor slip resistance as the users will find it over the longer term.

WARNING: SLIP RESISTANCE RATINGS

Variations in slip ratings are inherent in all batches of ceramic tiles and between tile products supplied by different manufacturers, as is the case with the colour, shade and sizing of ceramic tiles. A product’s stated Slip Rating is derived from an initial, single test batch of ordered tile product only. Slip resistant test results are not provided for any subsequent batches that may be manufactured.

Likewise, slip resistant test results are not provided for any gloss or polished finish tile, as these are clearly not slip resistant products.

Therefore, irrespective of whether a slip rating test has been provided for a selected tile product, the end user must acknowledge that these results can vary from batch to batch and agree that it is the end user’s (Architect, Builder, Property Owner) responsibility to obtain independent slip resistance testing and reports for all selected tile products to ensure their suitability, fitness for purpose, and safety.

Alstonville Tiles & Floorcoverings, to the extent permitted by law, are not liable for any loss, damages, or costs (howsoever arising) resulting directly or indirectly from the end user’s failure to obtain independent slip resistance testing and reports for all tile products and batches that they intend to order.

It is important to understand that the long-term effectiveness of any slip resistant flooring product, will be greatly diminished by inadequate cleaning and maintenance regimes. This also needs to be recognised by the end user (Architect, Builder, Property Owner) when specifying or placing an order for slip resistant products.

A simple Google search will provide end users with NATA accredited companies who can provide independent slip resistance testing, if required.